- Red Pepper Racing

- → Viewing Profile: Posts: tcrow1966

Community Stats

- Group Members

- Active Posts 98

- Profile Views 4053

- Member Title aka. Dos Habineros

- Age 57 years old

- Birthday August 29, 1966

-

Gender

Male

Male

-

Location

woodlawn IL. USA

-

Interests

ASE CERT. MECH.

Previous Fields

-

Drives

86 crx si ew-4 92 nissan sentra

-

Gallery

http://s236.photobucket.com/albums/ff36/tcrow1966/

0

Neutral

User Tools

Friends

tcrow1966 hasn't added any friends yet.

Latest Visitors

Posts I've Made

In Topic: Project Port Alignment

30 May 2008 - 07:06 AM

thank you guys for the info

In Topic: Project Port Alignment

06 May 2008 - 08:36 PM

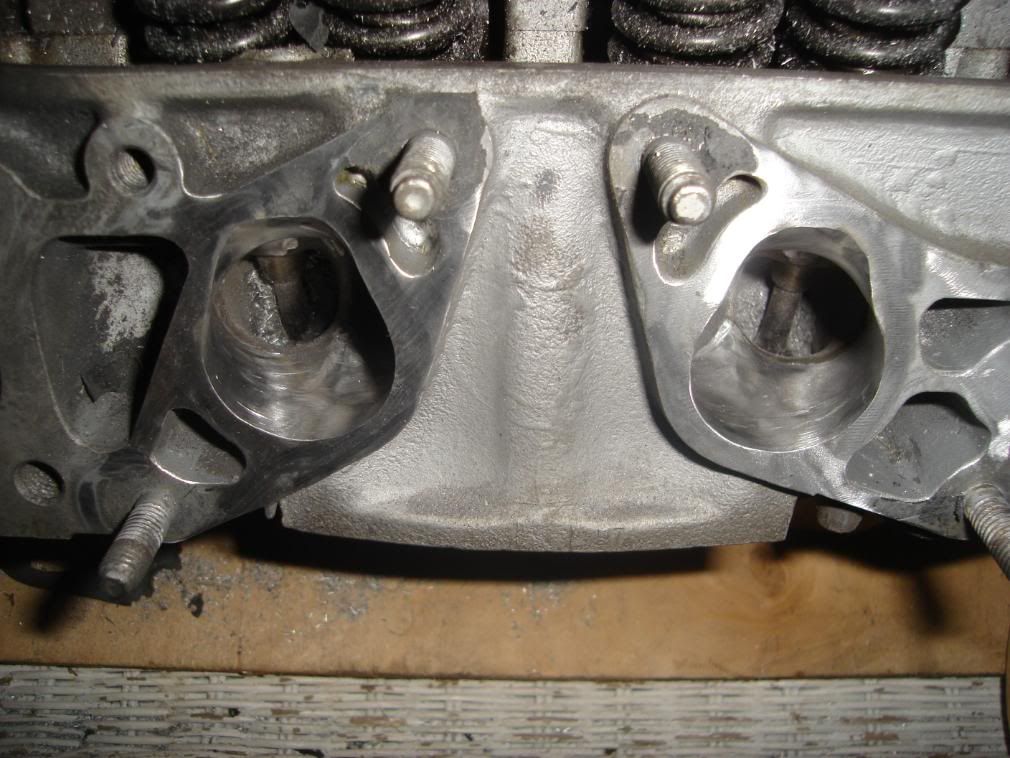

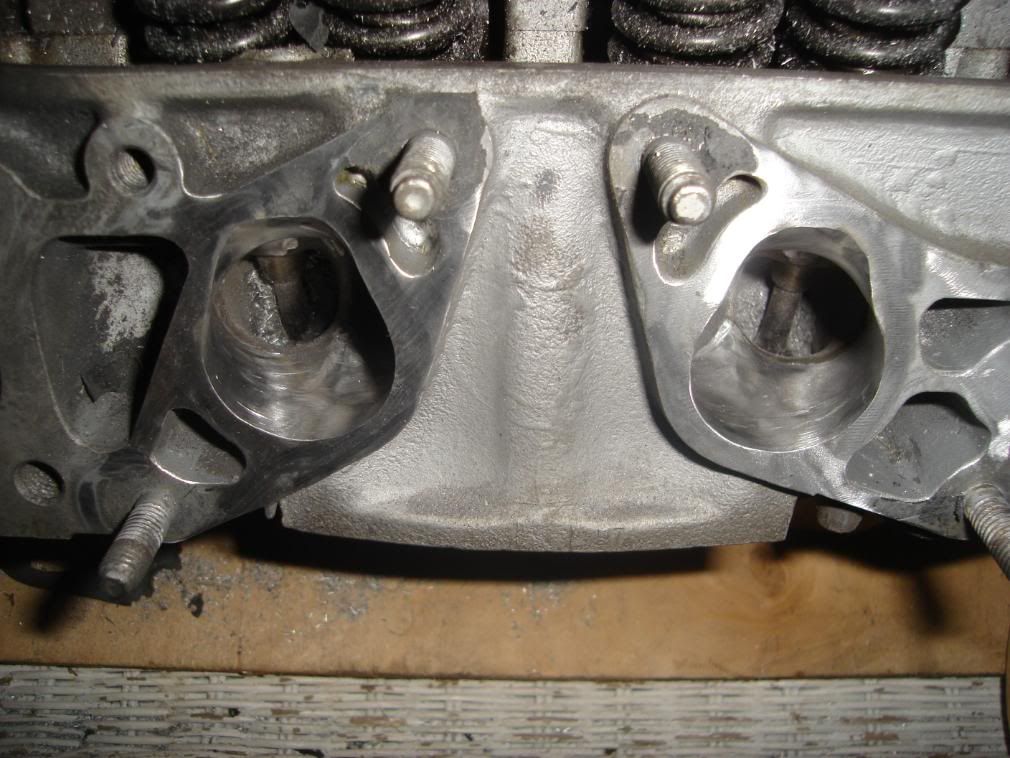

did the intake ports tonight here they are

what i'm doing with this head we did to my friends hornet car and it ran a he$$ of alot better same car same engine.anyway the post is called port alignment not porting and polishing. we all know the principle of the garden hose hold your thumb over the end you increase velocity not flow. remove your thumb water flows much more free. and if you kink the hose nothing flows. same principle applies to air. also if you use the same gasket on both sides intake and head using the bolts as a reference the ports will line up. and never in this thread have i said that i was polishing. this is a budget job not a high dollar race car.

just my $0.02

what i'm doing with this head we did to my friends hornet car and it ran a he$$ of alot better same car same engine.anyway the post is called port alignment not porting and polishing. we all know the principle of the garden hose hold your thumb over the end you increase velocity not flow. remove your thumb water flows much more free. and if you kink the hose nothing flows. same principle applies to air. also if you use the same gasket on both sides intake and head using the bolts as a reference the ports will line up. and never in this thread have i said that i was polishing. this is a budget job not a high dollar race car.

just my $0.02

In Topic: Project Port Alignment

06 May 2008 - 08:13 PM

QUOTE (lxndr @ May 6 2008, 06:26 PM) <{POST_SNAPBACK}>

I would never, ever port a head this way.

This is called gasket matching and serves a different purpose than port matching, all you are doing if reducing velocity by enlarging the gasket area only. The real problem is in the valve area and to properly port the head you will need to remove the valves in order to de-shroud the valve seats and smooth out the sharp bend on the floor of the ports.

Removing all the casting flash and texture is great, this helps promote swirl which helps atomization. But what's going on here will actually hinder performance.

The only reason to gasket match is if you are building an extremely hi-flow head and are enlarging to ports, intake runners and plenum. Port matching is what is done on a "street port" and is part of the full port and polish job I did on the motor that now resides in the Kakabox. Basically a port match ignores the size and shape of the gasket to some degree and focuses mainly on making sure the ports actually line up when the parts are assembled which helps promote velocity/performance.

Also, a grinding stone is not the proper tool for removing material from aluminum.

Just my $.02

This is called gasket matching and serves a different purpose than port matching, all you are doing if reducing velocity by enlarging the gasket area only. The real problem is in the valve area and to properly port the head you will need to remove the valves in order to de-shroud the valve seats and smooth out the sharp bend on the floor of the ports.

Removing all the casting flash and texture is great, this helps promote swirl which helps atomization. But what's going on here will actually hinder performance.

The only reason to gasket match is if you are building an extremely hi-flow head and are enlarging to ports, intake runners and plenum. Port matching is what is done on a "street port" and is part of the full port and polish job I did on the motor that now resides in the Kakabox. Basically a port match ignores the size and shape of the gasket to some degree and focuses mainly on making sure the ports actually line up when the parts are assembled which helps promote velocity/performance.

Also, a grinding stone is not the proper tool for removing material from aluminum.

Just my $.02

actually i haven't used the grinding stone at all it gums up .

In Topic: Project Phoenix

06 May 2008 - 12:33 PM

I have a 86 si and it only has a 120 mph speedo someone must have changed it

In Topic: Project Port Alignment

06 May 2008 - 12:23 PM

I would rather use a die grinder and scotch brite wheels if I had a compressor at home but my ex wife got that in the divorce. she also got my 7000.00 dollar matco box and about 40,000.00 worth of snapon and matco tools to. like she would know what to do with them she could bearly put gas in a car. LOL

- Red Pepper Racing

- → Viewing Profile: Posts: tcrow1966

- Board rules

Community Forum Software by IP.Board

Licensed to: Red Pepper Racing

Sign In

Sign In Create Account

Create Account

Find content

Find content