yeah man if you can make some goods for the rear that would be amazing! and depending on the style bar you use i may upgrade my existing Front Strut Bar

Testing Waters For New Product = Overhead Strut Bars

Started by chedda_j, Mar 27 2011 10:49 PM

58 replies to this topic

#16

Posted 28 March 2011 - 03:31 PM

Posted 28 March 2011 - 03:31 PM

#17

Posted 28 March 2011 - 03:56 PM

Posted 28 March 2011 - 03:56 PM

#18

Posted 28 March 2011 - 04:50 PM

Posted 28 March 2011 - 04:50 PM

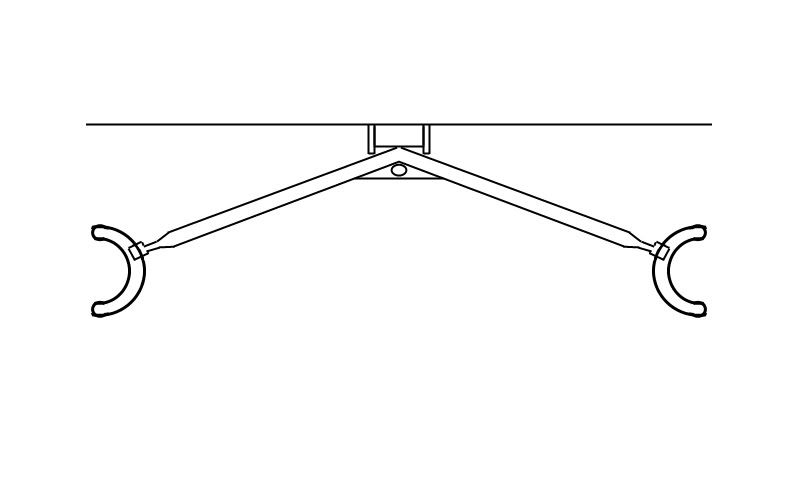

I will be making a jig from the first one i build. I know the third attatchment should be welded to the car, then it would come unbolted from that section like a pivot.

The rear bar that i would make, rather than being mounted to the suspension point, could have two flat bars, with four holes drilled in them, ready for four holes to be drilled in the strut towers. Then have two rod ends on pivots allowing you to tighten to desired tighteness. On the inside of the fender/strut tower, you would have to tighten the bolts, which would be typically cap screws.

I couldnt agree more with the panhard bar mount situation, il have to have a look when i get it back up on the hoist be from what i have seen, there isnt much to add support to, thin wall metal is a bitch. An interior support may suffice for more rigity but from there, im worried about breaking the mounts again. You have gaven me something to ponder about. The new trailing arm bushings are going to be made within the next week.

Ballade, i like that picture, that one looks to be prety strong, again tho, its going to end up right where the damn panhard bar mount is, so weither or not your really want to drill through the floor for two mounts there, is debatable. Im going to the shop tomorrow, and il have a better idea when im actually able to look at the rear of my car.

Like i have before, i would be offering each bar in payments, just like before. I may be able to get them powdercoated for effect, but again that will reflect costs.

#19

Posted 28 March 2011 - 04:52 PM

Posted 28 March 2011 - 04:52 PM

welded to the car is nice, but not easy or cheap for everyone. wasn't kaka's just bolted to the firewall? with a plate behind? seems like a simpler, cheaper solution.

QUOTE (kjeffery @ Apr 17 2009, 06:17 PM) <{POST_SNAPBACK}>

Yet again Scott, you have all the answers

QUOTE (cbstdscott @ Apr 17 2009, 07:31 PM) <{POST_SNAPBACK}>

No. All the answers are in the Kakabox build thread.

QUOTE (Lymitliss @ May 26 2009, 08:06 PM) <{POST_SNAPBACK}>

Ohh yeah I guess that makes sense. King Kaymo has all the answers

#20

Posted 28 March 2011 - 05:12 PM

Posted 28 March 2011 - 05:12 PM

QUOTE (kaymo @ Mar 28 2011, 03:52 PM) <{POST_SNAPBACK}>

welded to the car is nice, but not easy or cheap for everyone. wasn't kaka's just bolted to the firewall? with a plate behind? seems like a simpler, cheaper solution.

Obviously, thats why i mentioned that we should just have them bolted to the fire wall. This is the best universal way of making them.

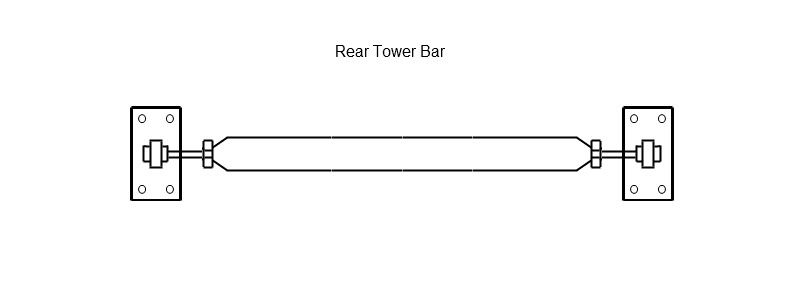

Heres the rear tower idea, but the ends will point towards the fenders no towards the back of the car like in the picture. It also shows the brackets just as square plates, but they will more defined and have a shape when mounted to the strut tower. Again i plan on using 1/2 or larger heims joints.

#21

Posted 28 March 2011 - 05:30 PM

Posted 28 March 2011 - 05:30 PM

is it really necessary to use heim joints for stiffening bars? that would really bring the cost down IMHO

QUOTE (kjeffery @ Apr 17 2009, 06:17 PM) <{POST_SNAPBACK}>

Yet again Scott, you have all the answers

QUOTE (cbstdscott @ Apr 17 2009, 07:31 PM) <{POST_SNAPBACK}>

No. All the answers are in the Kakabox build thread.

QUOTE (Lymitliss @ May 26 2009, 08:06 PM) <{POST_SNAPBACK}>

Ohh yeah I guess that makes sense. King Kaymo has all the answers

#22

Posted 28 March 2011 - 05:34 PM

Posted 28 March 2011 - 05:34 PM

QUOTE (kaymo @ Mar 28 2011, 04:30 PM) <{POST_SNAPBACK}>

is it really necessary to use heim joints for stiffening bars? that would really bring the cost down IMHO

No you dont have to use heims joints, you can just use a left hand and right hand rod that runs through a nut welded on the brackets. The rod ends just make it classy lol. The cost of making my own left hand and right hand rods and making the extra bracket piece will end up costing the same if not more. We could make the rear bar without any sort of adjustment, but from that, i think you will get alittle play and wont be able to stiffen it up as much as you woud like.

#23

Posted 28 March 2011 - 06:03 PM

Posted 28 March 2011 - 06:03 PM

can you not buy adjusters like the mazda toe links that kaka uses new anywhere? thats what i planned on unsing for mine

QUOTE (kjeffery @ Apr 17 2009, 06:17 PM) <{POST_SNAPBACK}>

Yet again Scott, you have all the answers

QUOTE (cbstdscott @ Apr 17 2009, 07:31 PM) <{POST_SNAPBACK}>

No. All the answers are in the Kakabox build thread.

QUOTE (Lymitliss @ May 26 2009, 08:06 PM) <{POST_SNAPBACK}>

Ohh yeah I guess that makes sense. King Kaymo has all the answers

#24

Posted 28 March 2011 - 08:36 PM

Posted 28 March 2011 - 08:36 PM

QUOTE (kaymo @ Mar 28 2011, 05:03 PM) <{POST_SNAPBACK}>

can you not buy adjusters like the mazda toe links that kaka uses new anywhere? thats what i planned on unsing for mine

Heims joints arent that expensive, they are only about 10 dollars a set, if a buy non-metric they are cheap. If i but metric they are a little more money.

1/2" i would think is more than strong enough, it also gives it that professional touch that you dont get with many strut bars.

Let me break it down for your.

5 feet of 1" structural tubing is $10

The heims joints are $10

The Jam nuts for left hand and right hand willl be a total of $5

The flat steel to make the brackets will be $10

Im guessing that each bar will take 4 hours to make, 1/2 can of 14 dollar rubberized spray paint per bar.

Your looking at a total of 42 dollars approx, plus shipping costs that i have to pay to get some of the materials, your looking at 60 dollars.

These will take me 4 hours to build total. I didnt plan on selling them for any more than 150 dollars, 170 shipped.

As you can see the material costs are going to save you a whole lot if you cheap out on part. There will also be some initial costs for me like buying the left hand tap and proper drill bit. Theres also the research time ext. In honesty its probably not going to work out more than 15-20 dollars an hour gross, - electricity and heat, gas and research . But thats how it goes, and i dont think its a bad deal for me or you.

#25

Posted 28 March 2011 - 11:42 PM

Posted 28 March 2011 - 11:42 PM

This will be another seriously awesome piece. The ONLY problem I see with making it a 3-point bar, is the fact that us few wagon owners could not utilize this AT ALL. Our firewalls are completely different, so with that said, if you can make it to where maybe the other bar(s) that would make it a 3-point piece could be made/ordered separately at an extra cost that would let us wagon owners and cheap asses still have a cool one off piece and still allow those that have a little more to spend to have something cool also.

Maybe make it to where the other 2 bars have their own brackets the would bolt over top of the single bar?

That way those of us who decided against (or just plain cant use) the other bars wouldn't have brackets on their shock towers that look like they are missing something

just some thoughts

-Garrett

Maybe make it to where the other 2 bars have their own brackets the would bolt over top of the single bar?

That way those of us who decided against (or just plain cant use) the other bars wouldn't have brackets on their shock towers that look like they are missing something

just some thoughts

-Garrett

#26

Posted 29 March 2011 - 12:21 AM

Posted 29 March 2011 - 12:21 AM

QUOTE (Gant @ Mar 28 2011, 10:42 PM) <{POST_SNAPBACK}>

This will be another seriously awesome piece. The ONLY problem I see with making it a 3-point bar, is the fact that us few wagon owners could not utilize this AT ALL. Our firewalls are completely different, so with that said, if you can make it to where maybe the other bar(s) that would make it a 3-point piece could be made/ordered separately at an extra cost that would let us wagon owners and cheap asses still have a cool one off piece and still allow those that have a little more to spend to have something cool also.

Maybe make it to where the other 2 bars have their own brackets the would bolt over top of the single bar?

That way those of us who decided against (or just plain cant use) the other bars wouldn't have brackets on their shock towers that look like they are missing something

just some thoughts

-Garrett

Maybe make it to where the other 2 bars have their own brackets the would bolt over top of the single bar?

That way those of us who decided against (or just plain cant use) the other bars wouldn't have brackets on their shock towers that look like they are missing something

just some thoughts

-Garrett

Hmm that is a fair idea, two singular brackets that hold two seperate bars towards the fire wall. That is a good idea. The way i imagined it, for the third mount would mount to a flat area on the firewall. Depending on the difference in distance from the firewall to the shock tower, it may not matter. Let me explain, when the bar is on two rod ends, at equal lengths towards the firewall, with a mount in the center, it should rotate towards the firewall untill it touches. From there you can drill and mount the third bracket for the centering mount. This may actually be the best way to do it all together because its going to solve the carb issue because the rods will point towards the firewall rather than over the valvecover.

#27

Posted 29 March 2011 - 12:43 AM

Posted 29 March 2011 - 12:43 AM

#28

Posted 29 March 2011 - 09:28 AM

Posted 29 March 2011 - 09:28 AM

QUOTE (kaymo @ Mar 28 2011, 04:03 PM) <{POST_SNAPBACK}>

can you not buy adjusters like the mazda toe links that kaka uses new anywhere? thats what i planned on unsing for mine

Just a FYI: The Kakabox does NOT use Mazda toe links, anywhere. I use rod ends, or heim joints. The Mazda toe links I did use was for a phb design that I ended up NOT using. Heim joints are readily available and relatively inexpensive.

RE. Triangulated Stb:

The firewall attachment for my triangulated stb is backed-up by a 3/16" heavy steel angle 'shear clip' that ties the vertical firewall to the horizontal 'wiper tray'. This hardpoint provides a stiffer load path for the diagonal stb rods. The firewall is too flexible to just connect the stb rods to it w/o a back-up reinforcement of some kind.

I don't use the OEM wiper linkages, so I don't know if they would fit w/this back-up structure in place. Just another thing to consider.

Oh, and if you put the back-up structure below the horizontal panel, be aware that the fuel hardlines are behind the firewall there (you can see the olive colored hardlines in the pic above).

J.

#29

Posted 29 March 2011 - 10:14 AM

Posted 29 March 2011 - 10:14 AM

i know kaka, i was talkin about the v1 panhard

QUOTE (kjeffery @ Apr 17 2009, 06:17 PM) <{POST_SNAPBACK}>

Yet again Scott, you have all the answers

QUOTE (cbstdscott @ Apr 17 2009, 07:31 PM) <{POST_SNAPBACK}>

No. All the answers are in the Kakabox build thread.

QUOTE (Lymitliss @ May 26 2009, 08:06 PM) <{POST_SNAPBACK}>

Ohh yeah I guess that makes sense. King Kaymo has all the answers

#30

Posted 29 March 2011 - 12:19 PM

Posted 29 March 2011 - 12:19 PM

QUOTE (chedda_j @ Mar 28 2011, 02:50 PM) <{POST_SNAPBACK}>

I couldnt agree more with the panhard bar mount situation, il have to have a look when i get it back up on the hoist be from what i have seen, there isnt much to add support to, thin wall metal is a bitch. An interior support may suffice for more rigity but from there, im worried about breaking the mounts again.

My version of a phb mount stiffener...

http://www.redpepper...e...st&p=243295

Triangulates the OEM phb mount to itself AND the floor. Back up angle connected to rear stb.

Note: If I were to do this again, I'd terminate the back-up angle triangulation at the rhs strut tower end of the stb. It's poor design practice to triangulate to another tube at midspan, like I did here. It's not as stiff of load path as terminating to an intersection of tubes or other triangulated structure. Design error on my part here.

Clears the HF axle tube (smaller dia then Si axle tube: ~2.2" OD for HF axle vs. ~2.5" OD Si) at full bump by .50"...

J.

Sign In

Sign In Create Account

Create Account

View Garage

View Garage Back to top

Back to top