I would never, ever port a head this way.

This is called gasket matching and serves a different purpose than port matching, all you are doing if reducing velocity by enlarging the gasket area only. The real problem is in the valve area and to properly port the head you will need to remove the valves in order to de-shroud the valve seats and smooth out the sharp bend on the floor of the ports.

Removing all the casting flash and texture is great, this helps promote swirl which helps atomization. But what's going on here will actually hinder performance.

The only reason to gasket match is if you are building an extremely hi-flow head and are enlarging to ports, intake runners and plenum. Port matching is what is done on a "street port" and is part of the full port and polish job I did on the motor that now resides in the Kakabox. Basically a port match ignores the size and shape of the gasket to some degree and focuses mainly on making sure the ports actually line up when the parts are assembled which helps promote velocity/performance.

Also, a grinding stone is not the proper tool for removing material from aluminum.

Just my $.02

Project Port Alignment

Started by tcrow1966, May 03 2008 08:57 PM

20 replies to this topic

#16

Posted 06 May 2008 - 07:26 PM

Posted 06 May 2008 - 07:26 PM

#17

Posted 06 May 2008 - 08:13 PM

Posted 06 May 2008 - 08:13 PM

QUOTE (lxndr @ May 6 2008, 06:26 PM) <{POST_SNAPBACK}>

I would never, ever port a head this way.

This is called gasket matching and serves a different purpose than port matching, all you are doing if reducing velocity by enlarging the gasket area only. The real problem is in the valve area and to properly port the head you will need to remove the valves in order to de-shroud the valve seats and smooth out the sharp bend on the floor of the ports.

Removing all the casting flash and texture is great, this helps promote swirl which helps atomization. But what's going on here will actually hinder performance.

The only reason to gasket match is if you are building an extremely hi-flow head and are enlarging to ports, intake runners and plenum. Port matching is what is done on a "street port" and is part of the full port and polish job I did on the motor that now resides in the Kakabox. Basically a port match ignores the size and shape of the gasket to some degree and focuses mainly on making sure the ports actually line up when the parts are assembled which helps promote velocity/performance.

Also, a grinding stone is not the proper tool for removing material from aluminum.

Just my $.02

This is called gasket matching and serves a different purpose than port matching, all you are doing if reducing velocity by enlarging the gasket area only. The real problem is in the valve area and to properly port the head you will need to remove the valves in order to de-shroud the valve seats and smooth out the sharp bend on the floor of the ports.

Removing all the casting flash and texture is great, this helps promote swirl which helps atomization. But what's going on here will actually hinder performance.

The only reason to gasket match is if you are building an extremely hi-flow head and are enlarging to ports, intake runners and plenum. Port matching is what is done on a "street port" and is part of the full port and polish job I did on the motor that now resides in the Kakabox. Basically a port match ignores the size and shape of the gasket to some degree and focuses mainly on making sure the ports actually line up when the parts are assembled which helps promote velocity/performance.

Also, a grinding stone is not the proper tool for removing material from aluminum.

Just my $.02

actually i haven't used the grinding stone at all it gums up .

When you conform to the norm you sink into obscurity.

I like to stand out.

Why be normal

I like to stand out.

Why be normal

#18

Posted 06 May 2008 - 08:36 PM

Posted 06 May 2008 - 08:36 PM

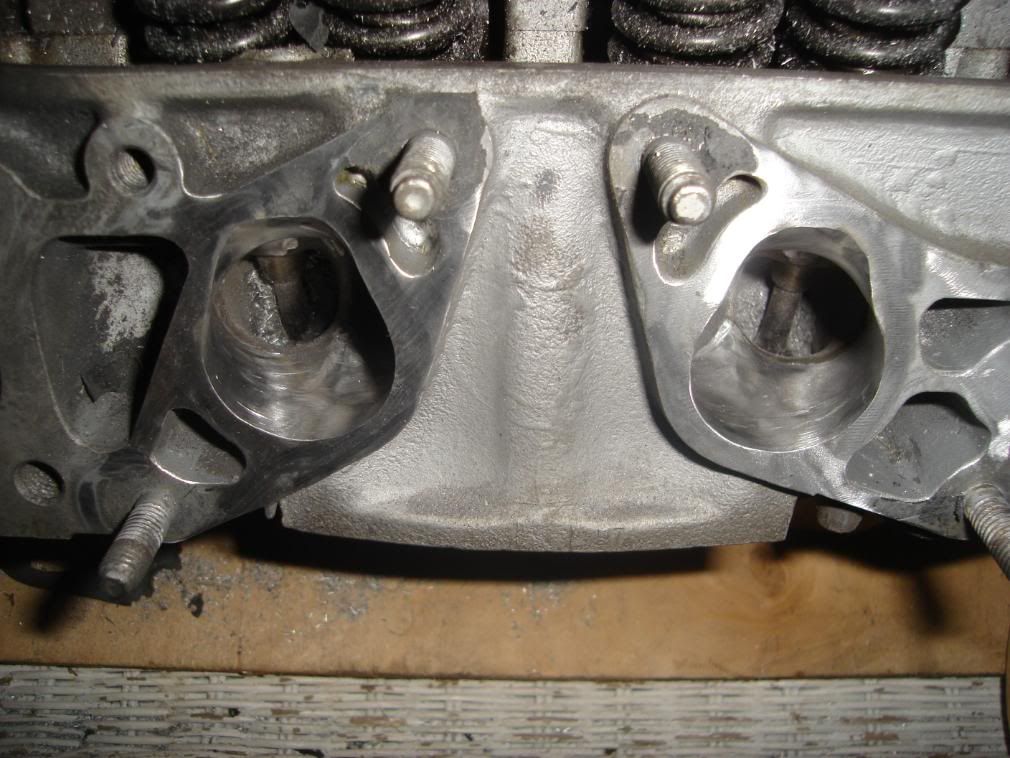

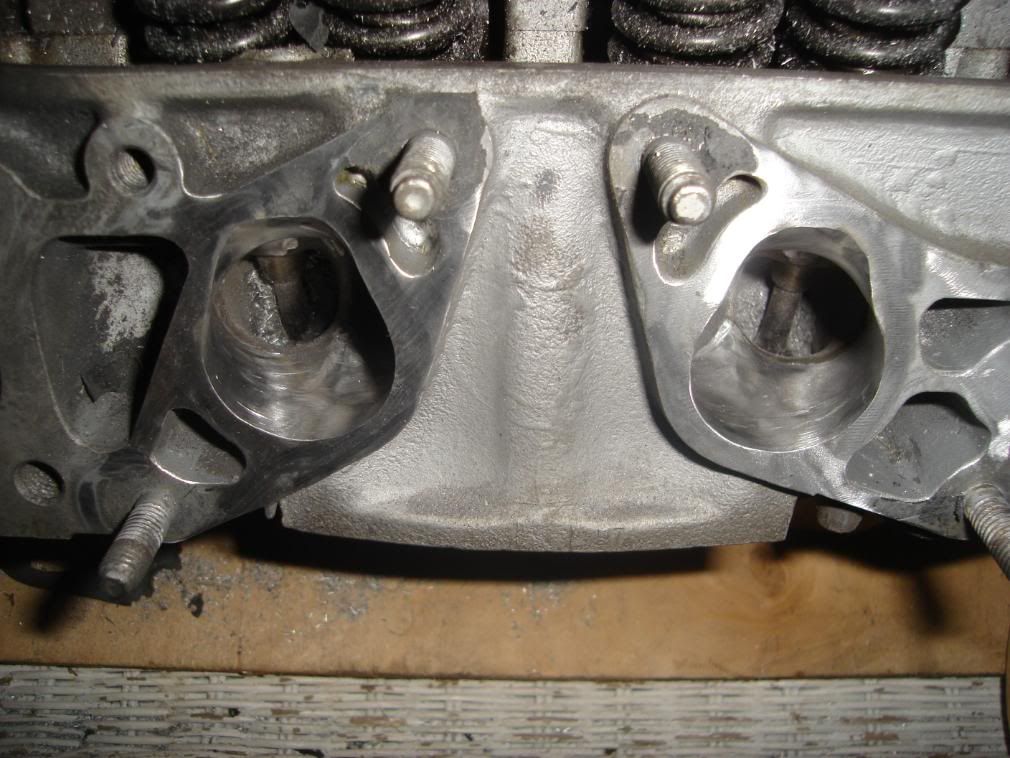

did the intake ports tonight here they are

what i'm doing with this head we did to my friends hornet car and it ran a he$$ of alot better same car same engine.anyway the post is called port alignment not porting and polishing. we all know the principle of the garden hose hold your thumb over the end you increase velocity not flow. remove your thumb water flows much more free. and if you kink the hose nothing flows. same principle applies to air. also if you use the same gasket on both sides intake and head using the bolts as a reference the ports will line up. and never in this thread have i said that i was polishing. this is a budget job not a high dollar race car.

just my $0.02

what i'm doing with this head we did to my friends hornet car and it ran a he$$ of alot better same car same engine.anyway the post is called port alignment not porting and polishing. we all know the principle of the garden hose hold your thumb over the end you increase velocity not flow. remove your thumb water flows much more free. and if you kink the hose nothing flows. same principle applies to air. also if you use the same gasket on both sides intake and head using the bolts as a reference the ports will line up. and never in this thread have i said that i was polishing. this is a budget job not a high dollar race car.

just my $0.02

Edited by tcrow1966, 06 May 2008 - 09:04 PM.

When you conform to the norm you sink into obscurity.

I like to stand out.

Why be normal

I like to stand out.

Why be normal

#19

Posted 21 May 2008 - 12:36 AM

Posted 21 May 2008 - 12:36 AM

I'm kind of shocked that you left the valves/springs in place while doing this. You did a good job with what you were trying to accomplish, but you should strip the head bare, then you can also remove some of the stem shroud and smooth the transition on the port floor like lxndr suggested. With all those metal bits flying around, that head could use a hot-tank anyway.

#20

Posted 22 May 2008 - 12:07 PM

Posted 22 May 2008 - 12:07 PM

QUOTE (nature223 @ May 5 2008, 02:46 AM) <{POST_SNAPBACK}>

the smoother your airflow with less turbulance/friction on the airflow mass the better your laminar flow(the ability to flow smoothly over a surface with minimal disturbance and resulting inhibition/turbulance to airflow over a surface it must ride over)

All pipe flow is turbulent after a few inches in. wall interference causes a parabolic velocity profile to form, no flow against the wall, max flow in center. It is good to maintain smooth, attached flow over components like a throttle plate (which see peak velocity). Don't knife edge it because it probably won't seal right anymore, and the leading edge should simply have the corners rounded for best flow. you can taper the rear, but be careful because you don't want any gaps when it's closed. you can also add some clay epoxy around the support shaft to smooth it out...however this is kinda risky in case it comes off.

Like Kaka said...I wouldn't port a head this way. you want to maintain or increase velocity in intake ports, not decrease. so decreasing cross-sectional area is used.

Tony Palumbo

'86 CRX Si ZC

'86 CRX Si ZC

#21

Posted 30 May 2008 - 07:06 AM

Posted 30 May 2008 - 07:06 AM

thank you guys for the info

When you conform to the norm you sink into obscurity.

I like to stand out.

Why be normal

I like to stand out.

Why be normal

Sign In

Sign In Create Account

Create Account

Back to top

Back to top