For one, has anyone who has devacced had any problems with the throttle sticking open? If you have a hand vacuum pump, with the car off draw vacuum on the secondary diaphragm and open the throttle. The throttle opens and won't close! The diaphragm is strong enough to hold the throttle plates open by the secondary linkage. This seems potentially dangerous to me... When you're devacced, part of the process we've been telling people to do involves connecting the secondary diaphragm to venturi vacuum. If the vacuum ever managed to be strong enough, one could run into the potential problem of being stuck on full throttle. Definitely not good. So has anyone run into this?

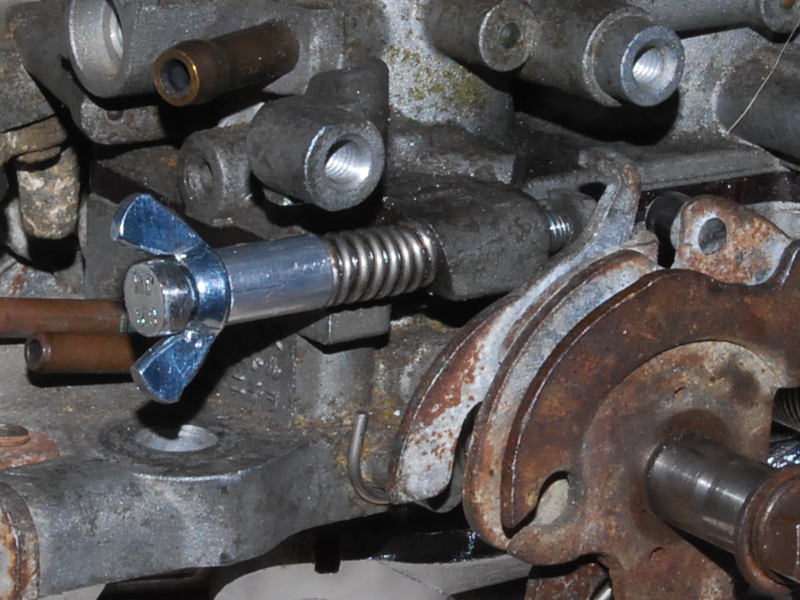

With a little research, I found a way to eliminate the vacuum diaphragm and convert our carbs to mechanical secondaries using just two zip ties! The carb is already basically a hybrid between vacuum and mechanical secondaries as it is, connecting the mechanical part of the secondary linkage to the normally vacuum controlled part is all that's necessary. The secondary then opens and closes at the correct time, completely mechanically.

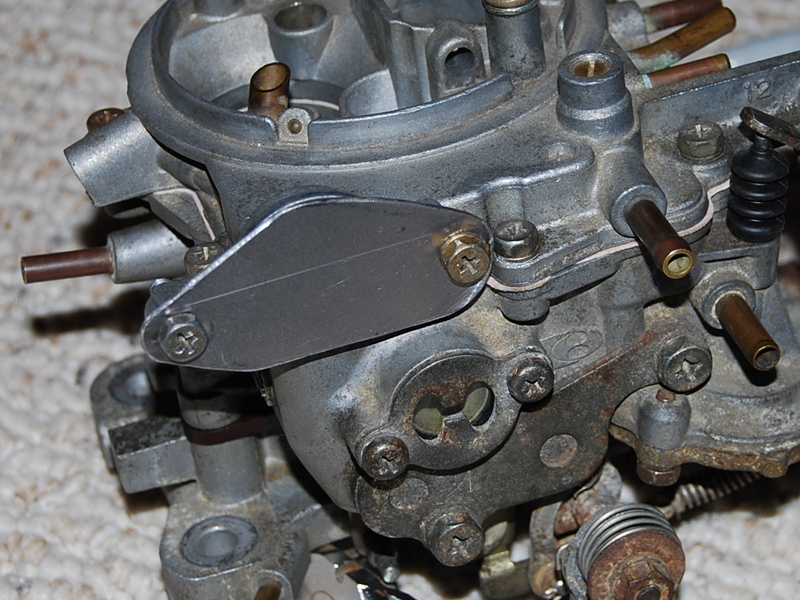

I was also removing every extraneous diaphragm and attachment from the carb. The choke and its diaphragms, secondary, AC, float bowl vent, everything. But I found that by removing the throttle control diaphragm, you lose the use of the idle control screw! The screw actually uses the diaphragm linkage as support; remove it, and the idle speed screw is useless. The canadian and Accord carbs have a little adjusting screw on the back of the carb with a black plastic knob on it to control their idle, while we have the screw on the front.

I discovered that our carbs also have this other adjusting screw! It doesn't have the plastic knob on it, and the screw head is blank; there's really no way to grab hold of it and turn it since it was never really meant to be used. It's just a placeholder screw, but it does have a tension spring on it to hold it's adjustment, and it does work! I plan on finding out the size of the threads, buying a longer one, and adding some kind of knob to the end, making a new idle adjustment screw!

With all the extra addons removed from the carb, it's very easy to rebuild, too. Pulled it apart, cleaned it out, blew all the passages clean, replaced the float valve and the accelerator pump diaphragm. At the bottom of the float bowl is the power valve. It's a little brass jet with a button in it that opens and closes to let additional fuel into the primary throat. It's normally open, and only closes when the emissions boxes detect certain conditions. That's why the port that controls the power valve is capped off when performing a devac. I removed it and tried to blow compressed air through one side. No matter how much pressure I put on it, I couldn't get any air to flow through it whether the little button was pressed or not. It was totally frozen in the closed position. I pulled the power valve out of another carb and tested it, and it worked great. With pressure on one side, pressing the button let a strong blast of air through it with no problem. This meant that the other power valve wasn't working at all. The valve isn't part of any rebuild kit, so there was no way to replace it. It's really just a jet with a valve in it, so I decided to remove the guts and make it a simple jet, since without any emissions equipment it was now always open anyway. I got lucky and found a good method to remove the valve mechanism and spring from the power valve without damaging the nozzle, turning it into a simple jet that won't freeze up and cause problems.

All this stuff isn't tested though... I plan to install my now heavily modified carb on my car this weekend and give it a shot to see how it runs. If the results are good, I'll do everything over again on one of my other carbs and take step by step pictures... to document Devac 2.0!

Edited by DarkHand, 08 June 2008 - 08:53 PM.

Sign In

Sign In Create Account

Create Account

View Garage

View Garage Back to top

Back to top