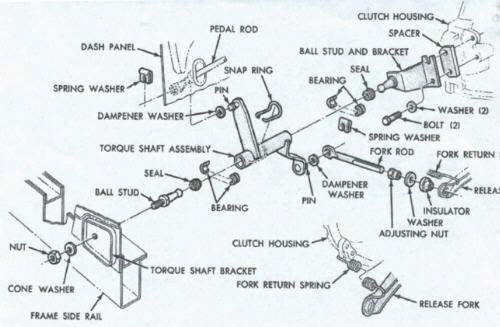

I messed around with some stuff at the junkyard and was wondering if the clutch master cylinder could be mounted to the firewall in the clutch cable hole location, if anyone has done this and could point me toward a thread I would be very grateful! Here are pics, The master cylinder does clear the power brake booster, but doesn't fully insert into the hole because of the clutch cable alignment brace/anchor. The other obstacle is that on the hydraulic clutch the clutch pedal pushes forward while on the cable clutch it pulls backwards. I thought about using something like a Z bar like on the Dodge/Plymouth clutch set up to transfer the backward direction of the cable clutch pedal to the forward direction needed to push on the master cylinder rod. Maybe someone has done this or has a better solution? It'd be nice not to reinvent the wheel. Heres the pics, they were taken on a CRX, 3G is a little different firewall but when I looked at my 3G it was almost the same with the same relative postition to the brake booster:

Edited by PuddleSkipper, 18 January 2012 - 04:46 PM.

Sign In

Sign In Create Account

Create Account

Back to top

Back to top

View Garage

View Garage