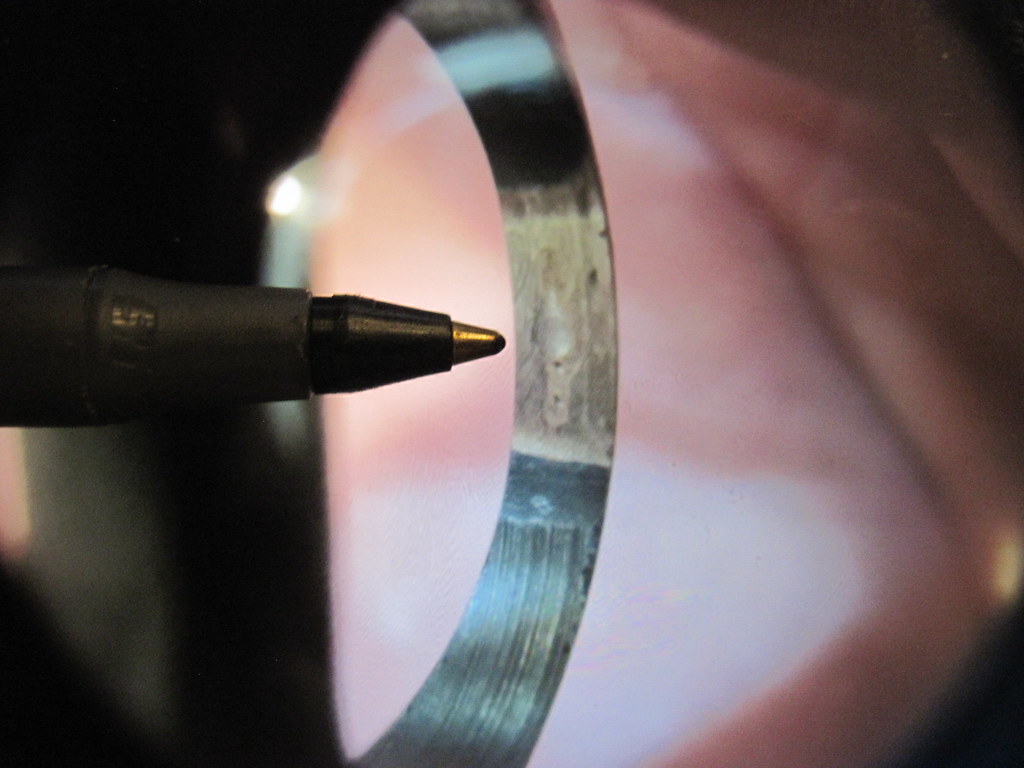

“Better Off Dead”. Watched the movie last night. Been a few decades. It’s Charles Dumar. Wasn’t his skis. But a guy holding this vintage set of Rossis in the background. Skiing the K12, not the K 2.

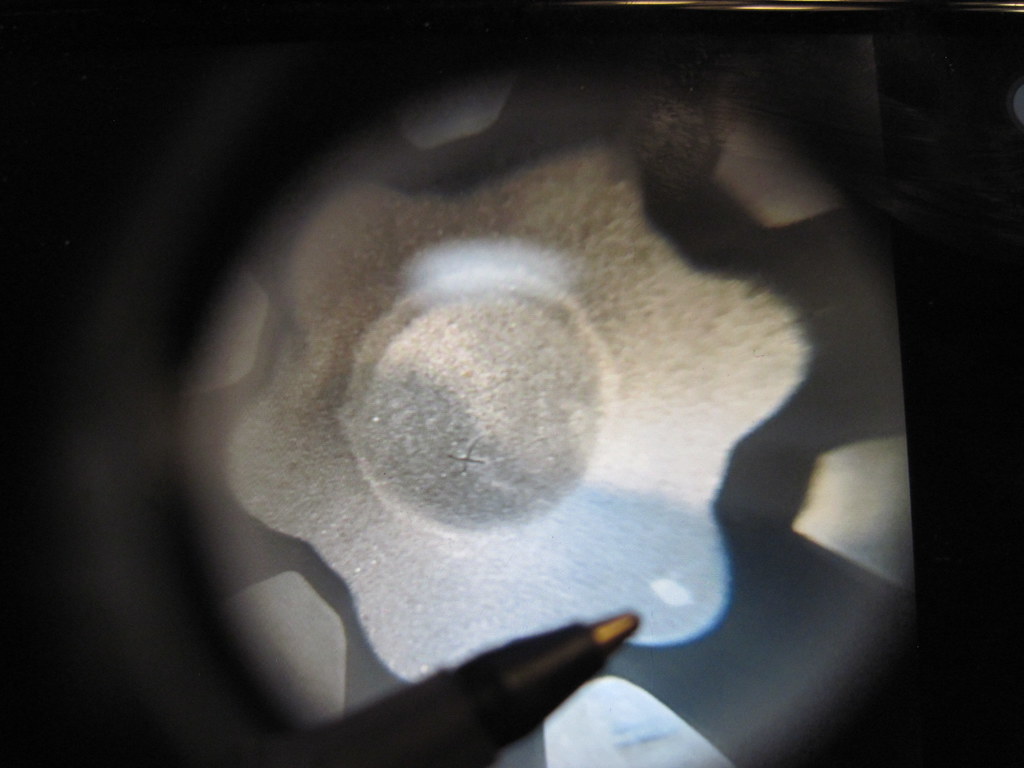

I remembered my skis were in this movie. I just couldn’t throw them away. Digging them out for Radwood

last time these skis were on my roof was back in the 1990’s in Vermont . The Rossis are behind the Volants. Can’t see them here

Sign In

Sign In Create Account

Create Account

Posted by

Posted by