All right, still working on the EF, Started the swap on Dec 30 so a little disapointed I'm not done yet. Hoping to get it done and switch back to the 87 or maybe the 2G CRX.

So this is my first swap, when I first tried to start it it wouldn't start. I sprayed ether in the air intake tube and it still wouldn't start, so not a fuel problem. Checked for spark, no spark, Checked power wire at coil, no power. Check for power on the rectangular plug on the fenderwell with the clear Yellow boot on it, it had power. I jumped a wire on the rectangular plug for the engine wire harness part and still didn't have power but then I touched the probe to the tach wire and I had power! I had made part of it into a piece that could be swapped out back to OBD0. The idea was that this harness could switch back and forth between OBD0 and OBD1. I think it was a waste of my time now and won't ever do it again.

So now I had power to my coil, but it still wouldn't start. No spark. So I checked all the wires to the ECU pins by running power from the distributor plug and checking with a test light with a T pin (found in the sewing section at your local store) taped on it with electrical tape. The tip of the probe was too fat to fit into the ECU plugs and didn't feel like going through the back side of the plug. They were all right, then however I noticed that the wires didn't match up with the wires on the distributor plug! It is a retangular plug so I imagine I had it flipped when I looked at it to pin in my wires. It started! Sucess! But it ran really rough, and tons of black smoke out the tailpipe (running rich). One code on the ECU which was for the coolant temperature sensor, probably why it was running rich. Ran power from the shock tower to the ECU, tested with a test light and had power, ran power to the plug, specifically the pin for the TW sensor, at the shock tower for the engine wire harness. No power. I bypassed it with a TW wire I pulled from the wire harness of the D15B2 that used to be in it.

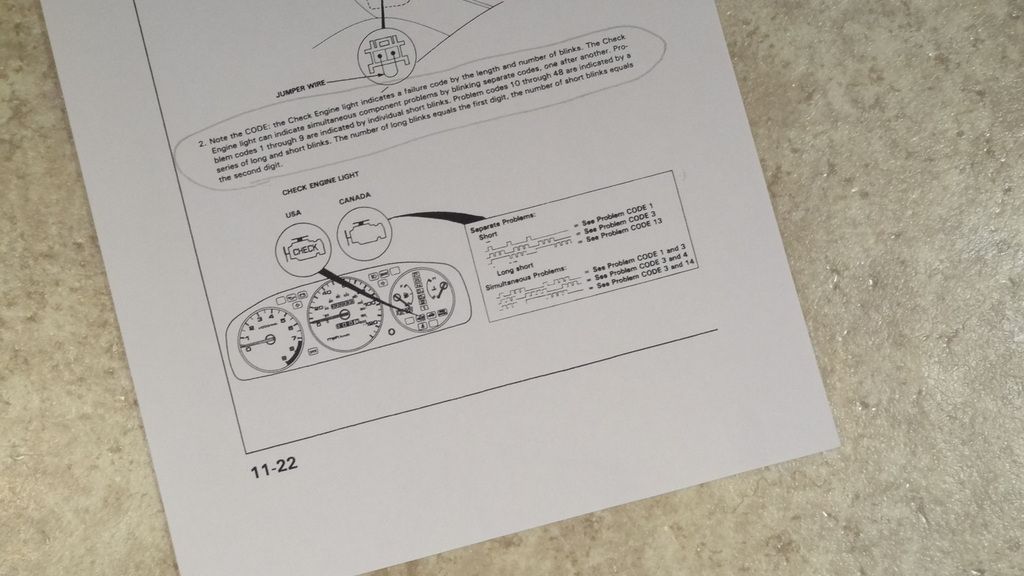

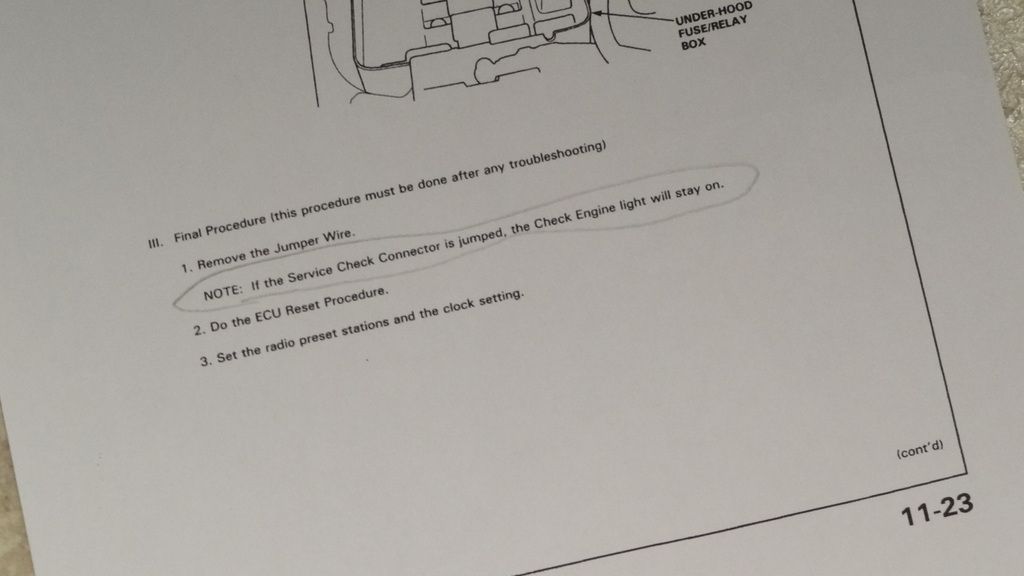

Pulled the negative battery cable to clear the codes. No check engine codes on start up, jumped the Service Check Connector (SCC) and the check engine light came on? From what I read here that is normal and what is supposed to happen. If a CEL pops up when you turn the car on without jumping the SCC, then you actually have a code. Jumping the SCC will light up the CEL, however, it is only when it is blinking is when it has a code. I found that info here:

http://honda-tech.co...umpered-460808/

All right, so no codes now, still have to tear apart the wire harness and replace the wire, but it's still running rough. I do a vacuum test on one of the lines and there is no vacuum but it's running? It's the same vacuum line my Map sensor is hooked up to................oh, it's vacuum line between the EGR Control Solenoid and the EGR valve! Duh, it's only getting vacuum when the EGR valve kicks on! No wonder it was rich! I know I need to break out the timing light and when I do the timing is about 10 degrees past TDC and I can't get any more adjustment out of the distributor. I found a couple of threads that said it had jumped a tooth. For me I had lined up the marks but when I tighted the idler pulley bolt that changed the mechanical timing. I moved it over a tooth and the distributor was finally firing where it should have with the timing light. It was still running rough and I could not get any more adjustment out of it. I questioned if I needed to go one more tooth over and then I found this:

http://honda-tech.co...timing-3213658/

So timing was right, it had fuel, but was still running rough. Still some black smoke out the tailpipe as well. So I did a power balance test. Pulling the plug on Cylinder 1 did nothing. I did a compression check with an extension on it (may lower the compression but not sure). Anyway compression was between 115 and 120 for all the other cylinders except #1 which had 80 lbs dry and 89 wet. Did a leak down test because I thought it might be the headgasket but it turned out to be the intake valves. Cylinder was at TDC and no valves were being pressed on. Bummer.

I did replace the head gasket and when I was cleaning the head mating surface up with laquer thinner I notice that some laquer thinner was leaking into the intake passage so I lapped the valves. The valve seats and valve lap surface had pitting in them, they were not rusty, just pitted. They were very difficult to lap because it took a lot of compound. Evidently cylinder #1 wasn't lapped or it's somehow got bent or was bent when I lapped it. Maybe I set it too hard on the bench? Who knows, so I'm getting another head rebuilt and I should be good! I'm very disapointed this happened, it's a JDM motor and they are supposed to test them before they send them out, also, it had a 1 year/unlimited mileage warranty. If I had installed this earlier I would have found this out and would have just warranted this out. Live and Learn. Next time I order a motor for a swap I will make sure that I am in a position I can run it before the warranty is up. I also decided to send the fuel injectors out to be cleaned to Pacific Fuel Injection. They clean them for between $15-$18 a piece, nice!

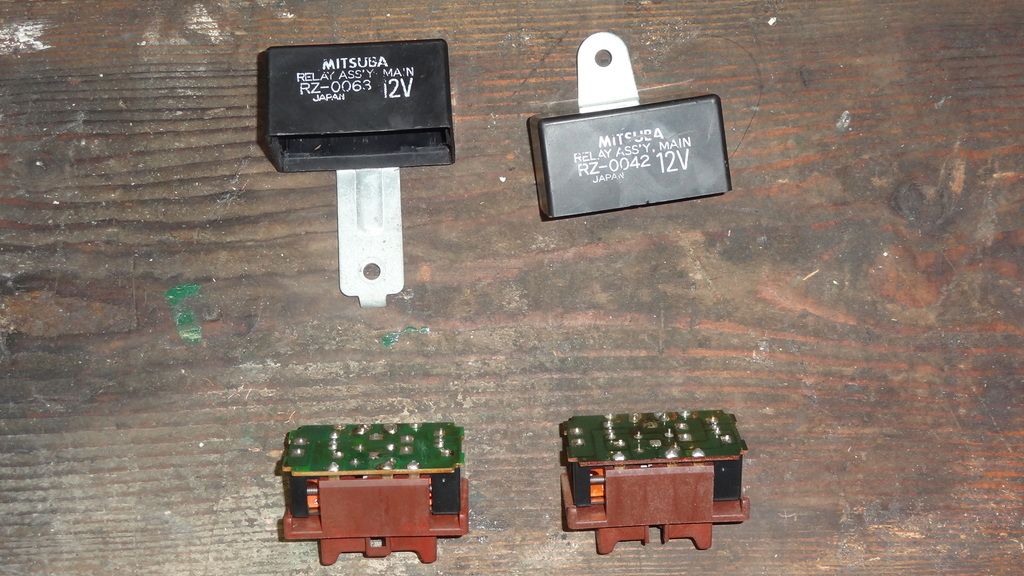

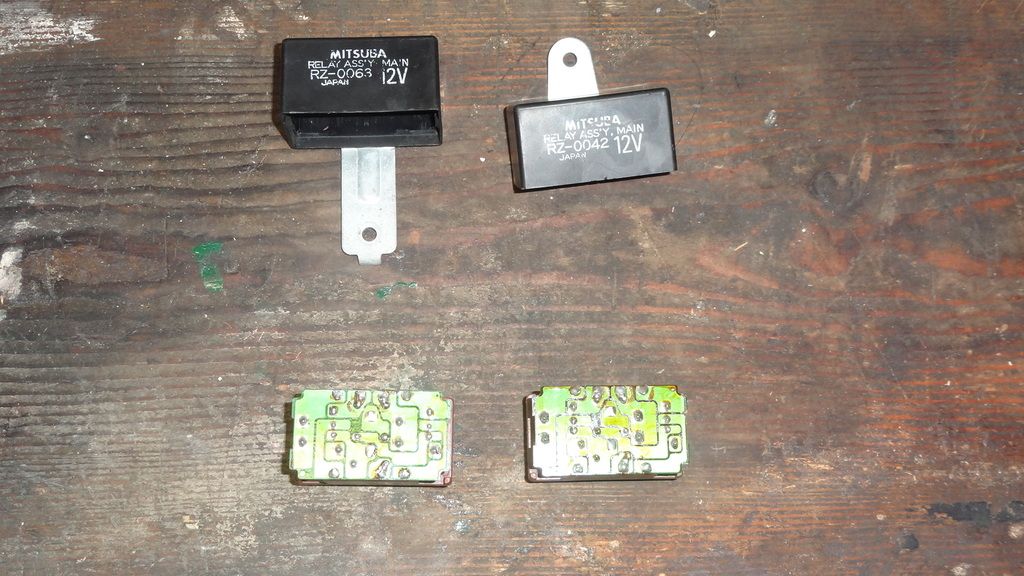

Anyway, if you are trying to trouble shoot electrical or build wire harnesses these alligator clips are invaluable! They go on the tips of your ohm meter and I think they are only $3 at radio shack!

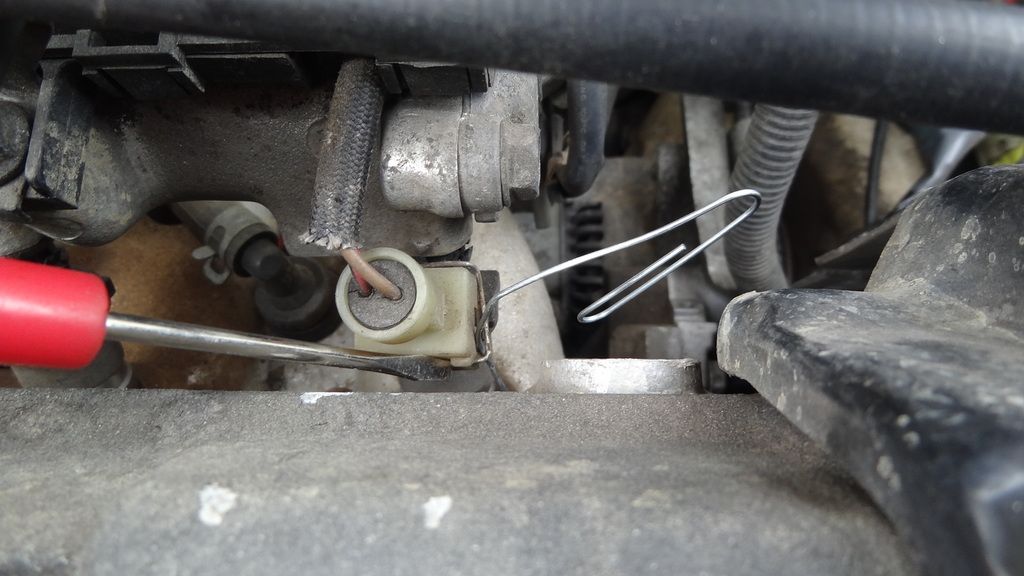

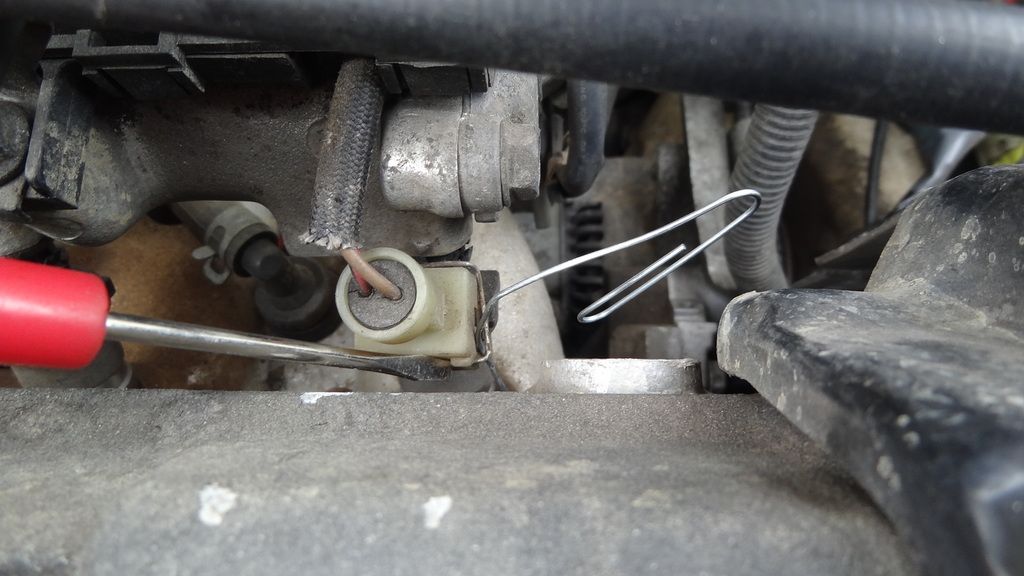

And I have always had trouble pulling the fuel injector clips but got a tip from a mechanic recently! I like using small zip ties the best, but here is a pic with a paper clip, you can really use anything though, even a chunk of wire would work. You just need a small screwdriver to pry it over and something like a ziptie or paper clip to hold it over. You probably only need to do one side and you can pry and pull the other side.

Edit 2/3/16: Added stuff I forgot about the map sensor

Sign In

Sign In Create Account

Create Account

Back to top

Back to top

View Garage

View Garage